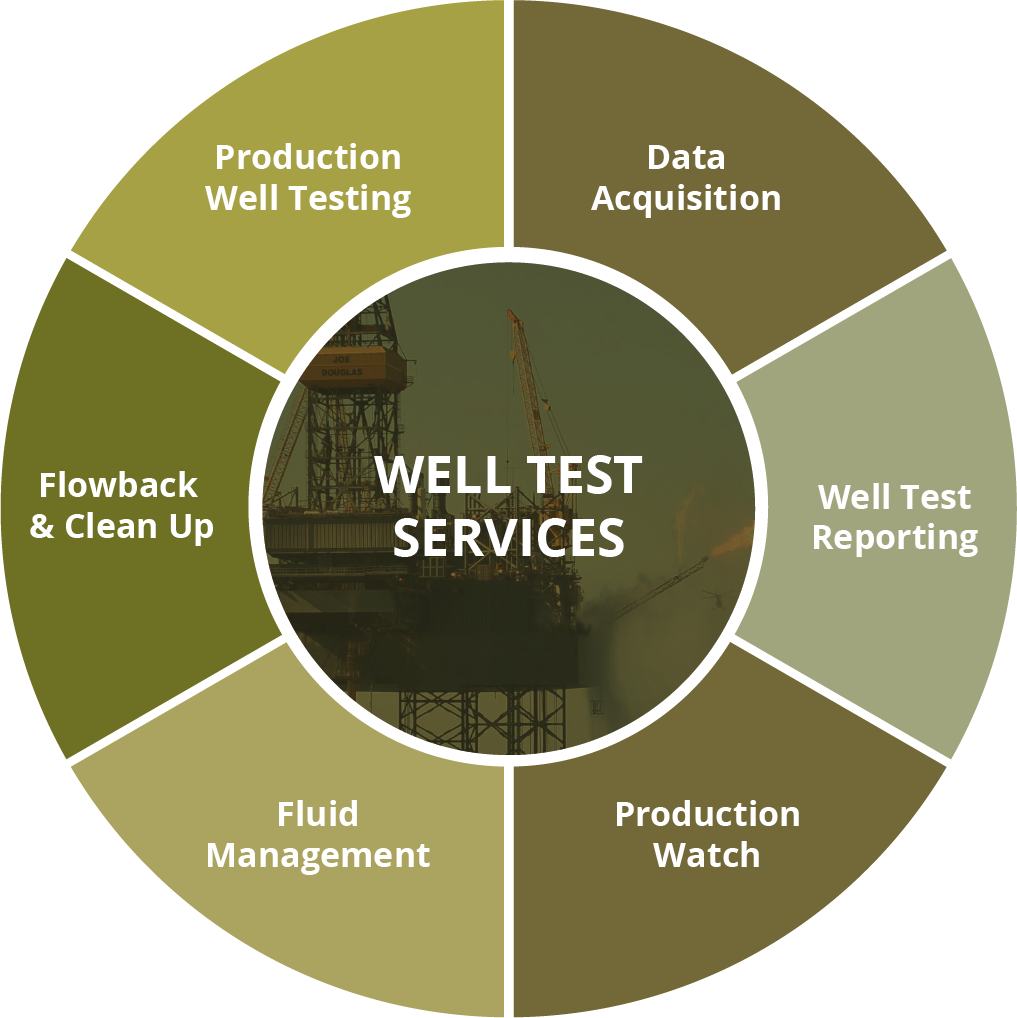

Well Testing Services

Longevity in the service industry demonstrates dependability, experience and keeping your word to customers. In 1972, Stric-Lan was founded as a well testing company. Remaining true to our roots, we continue to test some of the most prolific and problematic wells in nearly every region in the country. Our objective on every project is to efficiently and effectively meet and exceed the needs and goals of our clients.

It’s simple: we take a consultative approach by providing clients with custom solutions so they can focus on production. Our team of experts work together to provide customers with the right personnel and equipment to execute their project. In addition, customers also receive custom reporting and have access to 24/7 communication with operations and account managers because our customers are a top priority. Stric-Lan has proficiently executed services in over 5,000 ft. of water on floating deep-water rigs and platforms, and at 3,000 ft. of elevation on multi-well pads in the Marcellus and Utica Shales. We’ve worked on mountains in 20″ of snow and on 110°F days in the desert. These combined multidisciplinary experiences prove we can handle anything that comes our way.

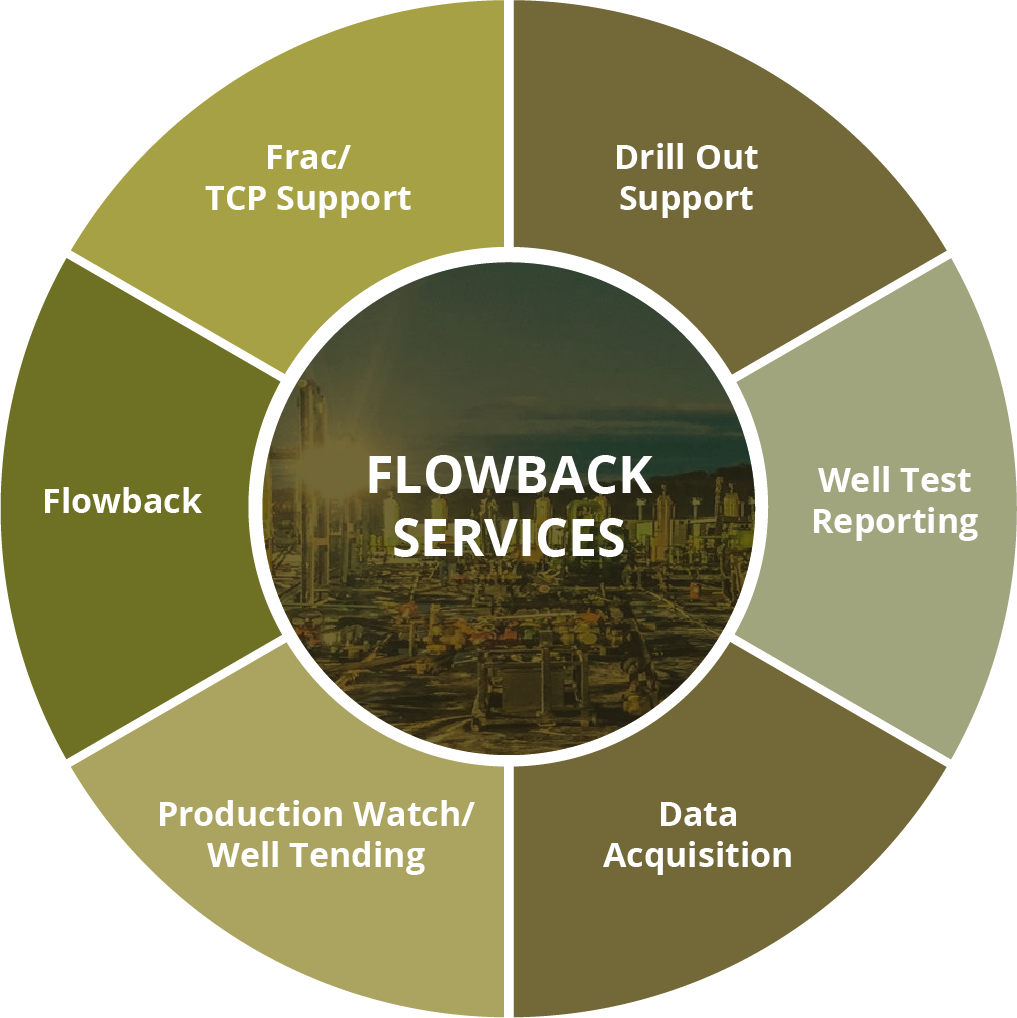

Flowback Services

The expertise developed during nearly fifty (50) years of well testing services has proven to be very useful in flowback operations. In fact, the lines have blurred significantly and occasionally overlap. Our experience in testing some of the most prolific wells in the world has been very useful in flowback large pads with 5, 6, 7 or even 10 wells. Our objective on every project is to efficiently and effectively meet and exceed the needs and goals of our clients.

We have tested wells in many areas of the U.S. including, but not limited to:

- Utica

- Marcellus

- Permian

- Haynesville

- Eagle Ford

- Granite Wash

- Tuscaloosa Marine

- Cotton Valley

- Austin Chalk

We, along with our customers, believe that our consultative approach serves to allow for proper preparation so that our clients can focus on other things while being confident in our ability to get the job done. Our team of experts work together to provide customers with the right personnel and equipment to execute their project. In addition, customers also receive custom reporting and have access to 24/7 communication with operations and account managers because our customers are a top priority.

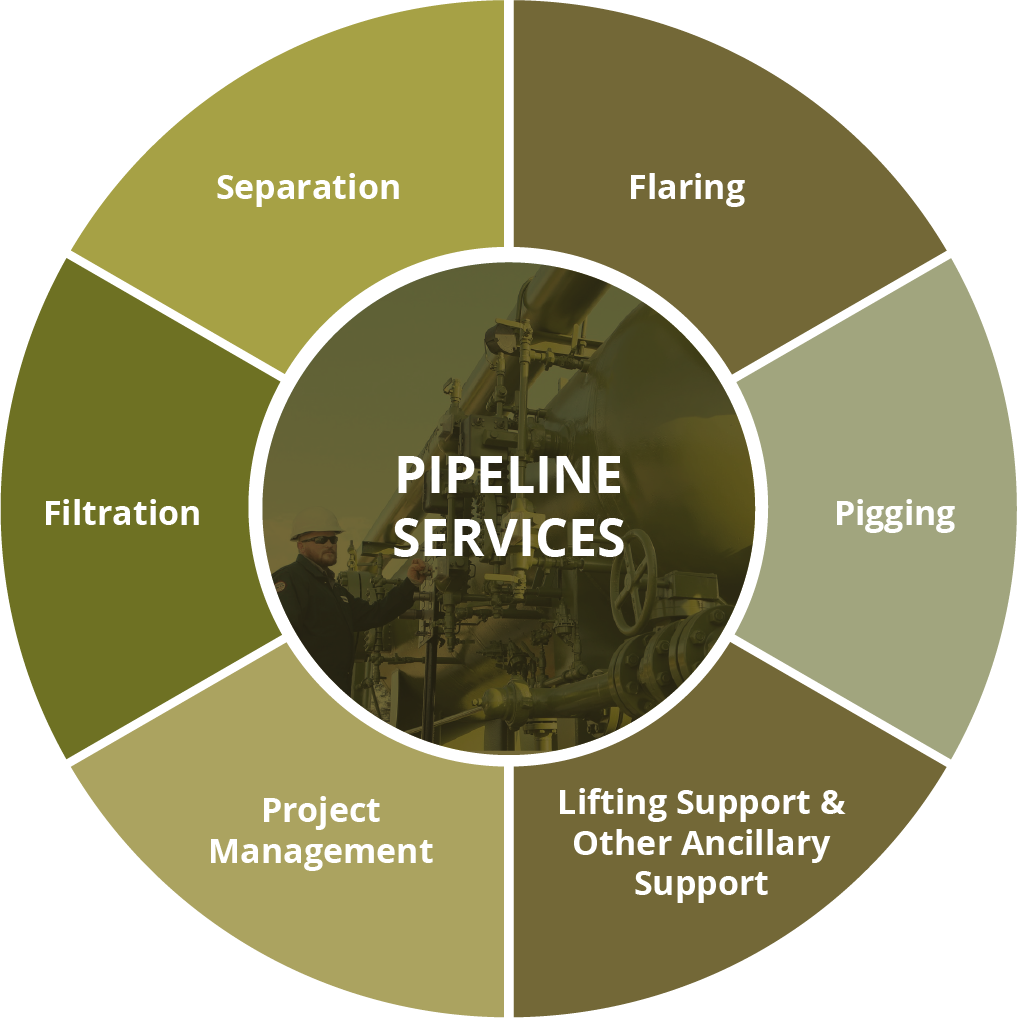

Pipeline Services

Stric-Lan Companies Pipeline Service group is a key part of Stric-Lan’s services, with a reputation for exceptional service developed on pipeline service jobs since 1995. Through the years, we’ve provided pipeline services in almost every state, including Alaska and Hawaii. We’ve built our reputation by providing the right experience, equipment and support critical to maintaining service quality and compliance in a very competitive and ever-changing industry. Experience has shown we can efficiently manage any project, including separation, filtration, slug catching, pigging, lifting & project management.

Stric-Lan offers a suite of services for new and existing pipelines of all sizes, lengths and types throughout the continental United States. We also have rental equipment including launchers, receivers, separators, filter housing, etc. These services are provided from multiple locations including Duson, LA, and Bulger, PA. Stric-Lan’s pipeline division operates nationwide.

Our unique Total Containment Package™ provides a primary high-pressure separator that permits safe, automated handling of extremely high liquid and gas rates. This is followed by a low-pressure secondary containment unit, which allows for a step-down of line pressures increasing retention times. The gasses can be vented or flared off, resulting in the total containment of all separated product.

The Stric-Lan TCP package has proven to be the safest, most effective and compliance friendly system on the market today. Stric-Lan can operate online or offline.

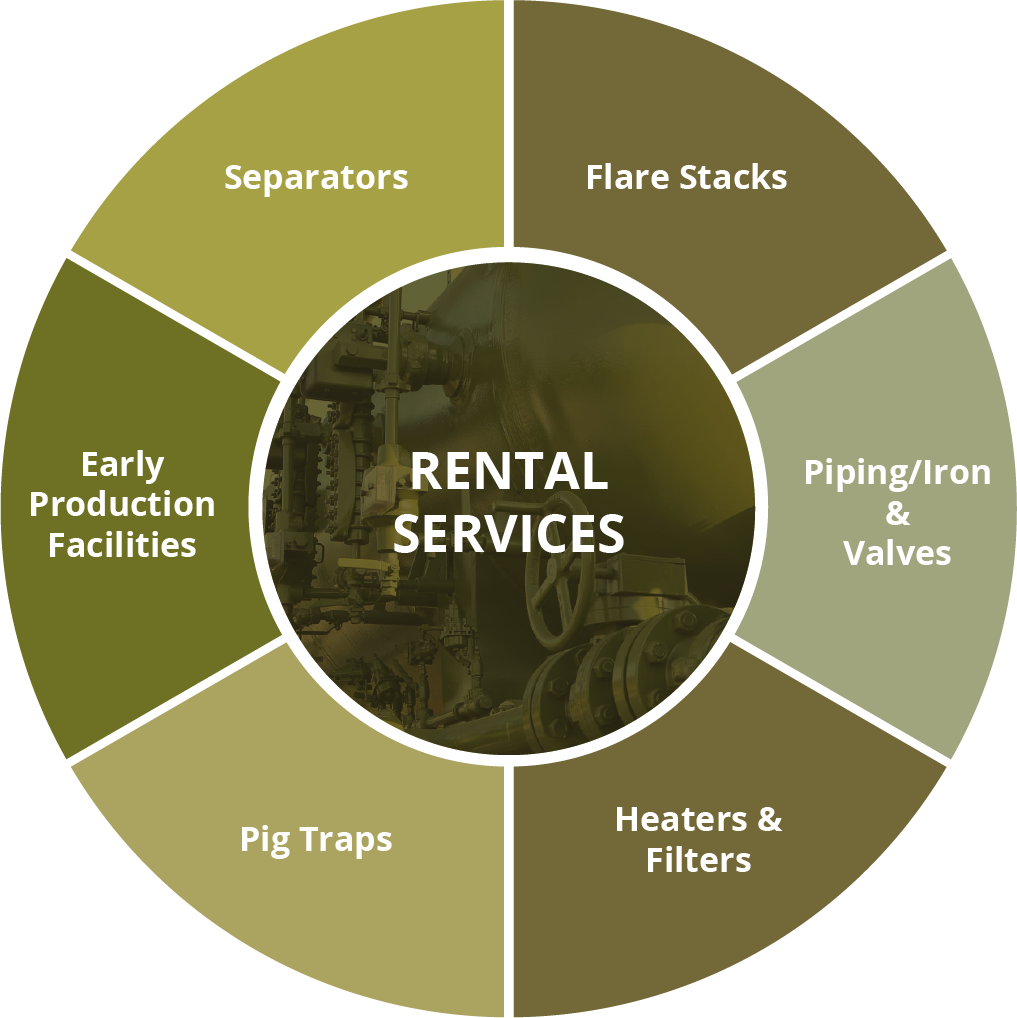

Rental Services

Stric-Lan has a full compliment of equipment that is available for short or long term rental. Stric-Lan equipment can be rented separately or as a packaged deal, with or without personnel. Our packages are fully customizable.

Stric-Lan has yards located in the Gulf Coast and in Appalachia, with staging areas across the country. We pride ourselves in our ability to move quickly but efficiently. We can often mobilize equipment to other states on short notice. Our equipment will arrive at location, certified, and job ready. Detailed information will be made available in advance upon request.

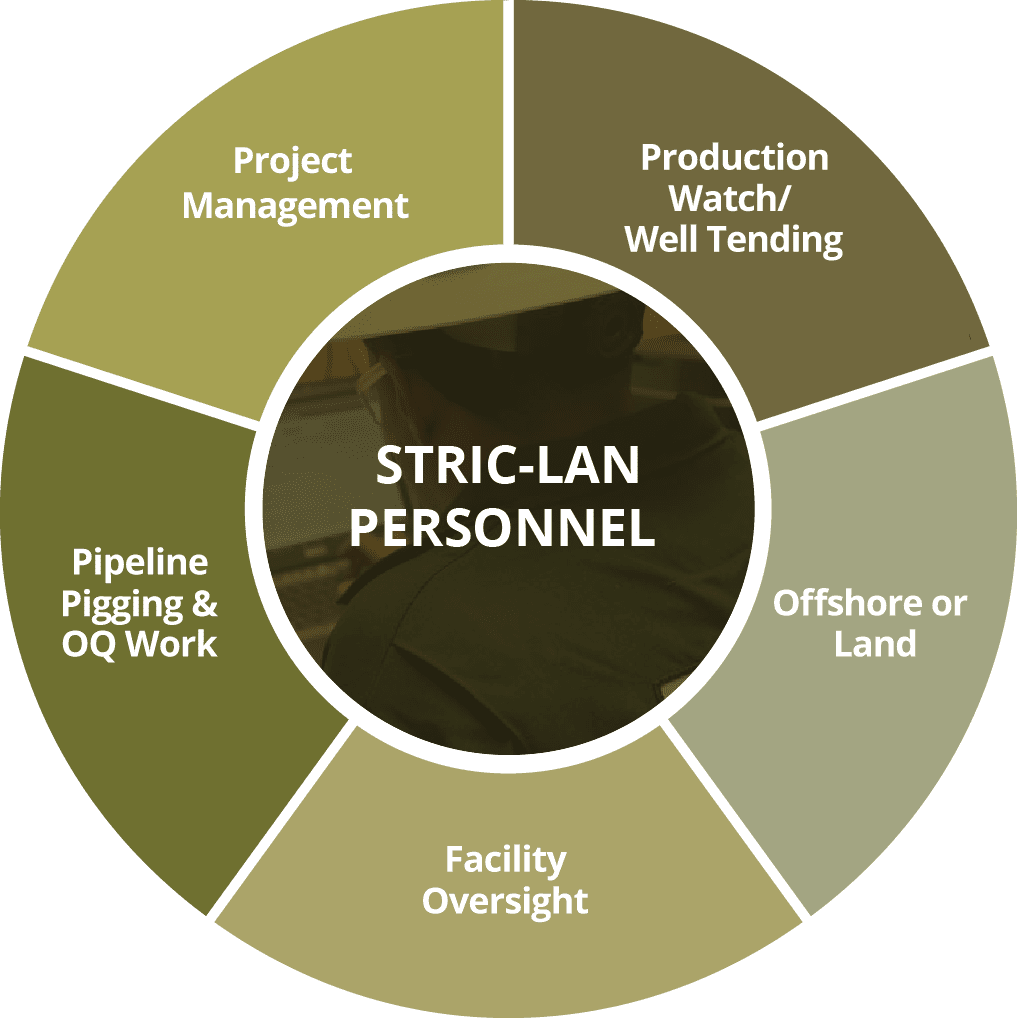

Personnel Services

Great employees represent our key competitive advantage. Expertise, experience, diligence and overall competence are often the primary reason a job is a success or a failure. Planning and preparing are hugely important, but when the unexpected happens, you need someone who’s been there and successfully navigated the challenges that nature presents.

Stric-Lan is known for its experience and could not have that without a great relationship with our people. During the 2020 COVID crises, Stric-Lan decided to keep its best, most experienced personnel. Many companies went a different direction – cutting costs first. We knew that our core values would not be represented without our best people.

Stric-Lan has always had long term personnel, and currently, the company has multiple 30-yr, 25-yr, 20-yr and 10+-yr employees. Our average employee currently has over 12 years’ experience in the oil and gas industry.

Safety, training and excellent service are at the top of Stric-Lan’s priority list. We have strict policies in place to ensure our priorities continue to align with the company’s vision for growth. Although we like to promote from within, we are always scouting for fresh talent with the aptitude to excel.

Please check out our safety link to view our excellent safety record and training programs offered.

Frac/ TCP Support

Stric-Lan has extensive experience with Frac and TCP support services. For over a decade, we’ve been trusted to handle support services such as Frac/TCP support and work in conjunction with other vendors as necessary to achieve the customer’s desired outcome.

Drill Out Support

Stric-Lan has completed 400+ plug drill outs on 10+ well pads on high-rate wells. The need for experience to maintain the properly balanced flow rates through our equipment is extremely critical, and we have plenty of experience to bring to the table.

Our arsenal of equipment includes vertical and horizonal plug catchers with nine and ten valve options.

Flowback

Flowing back a pad can mean a lot of variability in terms of pressures, volumes, rates, gravities, and more. Stric-Lan has extensive experience with large pads, high liquid and gas rates, high pressures and high gravity condensates. 10 well pads, over 400 plugs and very high pressures and rates are not going to get in the way of Stric-Lan’s mission to provide the best service and give the customer comfort that the job will get done the right way the first time out.

- High pressure Utica wells in Eastern Ohio and Western Pennsylvania

- High volumes of high gravity condensate in areas such as Wetzel Co., WV

- High volume gas rate wells in West and Southwestern Pennsylvania

- Northern West Virginia including Mon, Marion, Marshall, Wetzel, Harrison, Tucker

- Central PA and Northern PA

Well Test Reporting

Our reports are fully customizable and sent as a PDF. We also include the raw data in a CSV file that can be uploaded to Excel or the software of our client’s choosing. We are also able to use proprietary reports provided by the customer if that is preferred.

Data Acquisition

Production Watch/ Well Tending

Stric-Lan’s experienced and highly professional personnel can monitor and maintain production operations at times of low personnel availability, during system upsets or during major projects, during which personnel are called to work elsewhere. Even large facilities are within our capabilities for short- or long-term assistance.

Production Well Testing

Surface-based production well testing, testing a well utilizing portable production equipment is the sole approach available today to consistently gain reliable reservoir potential data under real-world and real-time dynamic environments. This technique allows for more accurate reservoir monitoring and generates the most accurate long-term outlook for production output over time.

Stric-Lan provides well testing services on land and offshore including, but not limited to:

- Well and reservoir appraisal testing

- Well clean-up and unloading

- Production testing

- Fluid management and measurement

Data Acquisition

Stric-Lan has the ability to provide a wide variety of data acquisition options including, but not limited to:

- Memory Surface Data Acquisition

- Real-time Data Acquisition

- Detailed Graphs and Charts

- Professional Reporting

Production Watch & Well Oversight

Stric-Lan’s experienced and highly professional personnel can monitor and maintain production operations at times of low personnel availability, during system upsets or during major projects, during which personnel are called to work elsewhere. Even large facilities are within our capabilities for short- or long-term assistance.

Flowback & Clean Up

Cleaning up, or flowing a well until the production equipment can take on the well bore fluids without system upsets from various solid or liquid contaminants, is a large part of the traditional well testing process. Utilizing portable production equipment to take on solids, introduced slurries and chemicals, waters and/or other fluids or solids that can create problems in the production process can pay huge dividends. It’s likely, Stric-Lan has performed more flowbacks and cleanups in the Gulf of Mexico and along the Gulf Coast than any other company.

Our clean-up packages include:

- Clean-up including production equipment and completions

- High-rate gas and liquid flow rate measurement

- Water handling to deliver for treatment purposes

- Solids removal

Well Test Reporting

Our reports are fully customizable and sent as a PDF. We also include the raw data in a CSV file that can be uploaded to Excel or the software of our clients choosing. We are also able to use proprietary reports provided by the customer if that is preferred.

Fluid Management

Stric-Lan can handle directing and managing well bore fluids in many different situations. Accurately measuring fluids is critical in both the completions and production phases. Environmental factors including disposal and potential loss of containment are key issues that must be addressed through the proper systems; excellent, well maintained equipment and experienced personnel.

In addition, recovery and reuse of drilling and completions fluids through properly flowing the well can save tremendous costs. Finally, reducing potential non productive time (NPT) and improving safety go hand-in-hand with proper management of the various well bore fluids and effluent that are second nature to Stric-Lan.

Separation

Stric-Lan has its roots in separation work. Our production well testing background led clients to request large separation units to be utilized during pipeline cleaning and purging activities. This means that Stric-Lan’s large inventory of separators always has plenty of knowledgeable personnel to operate the units. All of our personnel are properly OQ trained and drug screened. Stric-Lan has completed separation jobs in all 50 states, Mexico and Brazil.

Among the jobs completed:

- A 1.1 Bcf Job in California that required 3 large units.

- Multiple jobs with 250-400 mmscf in various portions of the country.

- A several hundred-mile-long line with multiple locations in Texas.

- 100,000 bbl/day liquid job in Texas with HP and LP separation.

Flaring

Flaring Services

Stric-Lan has delivered high-quality Pipeline Services since 1995. We offer a wide variety of services including Flaring, Separation & Filtration. Stric-Lan can work online and offline.

Experience

- Multiple personnel with over 20 years’ experience

- Experienced flare personnel on our jobsites

- Pre-job consultation process maximizes efficiency and quality of operations execution

- Flaring jobs with over 80mmscf in gas

Advantages

- Rapid rig-up and rig-down

- Ability to burn a wide variety of product

- 98% destruction rate at given job conditions

- Flare line scrubbers available to remove entrained liquids

- Flame arrestors or check valves made available for each job

Filtration

Our filtration packages can be used on liquid and gas lines. Multiple units can be tied in together to handle very high rates with no downtime due to the ease of changing out filtration cartridges. Quick opening doors allow for a rapid change out of cartridges after bleeding off pressure. Tying two or more units together ensures that no solids get past our units.

Experience includes:

- An 8-filter job in Boston, MA with high-rate gas

- Huge liquid line purge in South Texas requiring 10 filter units

Pigging

Stric-Lan possesses multiple OQ certified and experience personnel who can provide pigging expertise for any situation. Stric-Lan provides pigging services including:

- Mechanical Cleaning

- Drying

- Progressive Pigging & Cleaning

- Pigging Oversight & Management

Lifting Support & Other ancillary support

Stric-Lan has an extensive background providing lifting support on a wide variety of ‘smart’ pigs all over the country. The importance of ensuring that expensive tools can be entered into and out of the launchers and receivers properly cannot be overstated.

Project Management

Stric-Lan’s OQ trained project managers can handle any operation – large or small; online or offline; processing facilities and plants; or, any circumstance you can think of. We can handle your project so that you can stay focusing on the most important issues and not have to delay projects or add personnel on a short term basis.

Separators

We often have multiple units available in select sizes.

TEST SEPARATORS – TRAILER MOUNTED SINGLE STAGE

- Separator – 24″ x 8′ – 1440psi – 3 phase – Trailer Mounted

- Separator – 24″ x 10′ – 1440psi – 3 phase – Trailer Mounted

- Separator – 30″ x 8′ – 1440psi – 3 phase – Trailer Mounted

- Separator – 30″ x 10′ – 1440psi – 3 phase – Trailer Mounted

- Separator – 60″ x 18′ – 1440psi – 3 Phase – Trailer Mounted

TEST SEPARATORS -SKID MOUNTED SINGLE STAGE

- Separator – 30″ x 8′ – 1440psi – 3 phase – 4″ Meter – Skid Mounted

- Separator – 30″ x 8′ – 1440psi – 3 phase – 6″ Meter – Skid Mounted

- Separator – 30″ x 10′ – 1440psi – 3 phase – Skid Mounted

- Separator – 30″ x 8′ – 1440psi – Flanged – 3 phase – Skid Mounted

- Separator – 36″ x 10′ – 1440psi – 3 phase – Skid Mounted

- Separator – 42″ x 15′ – 1440psi – 3 phase – Skid Mounted

- Separator – 48″ x 10′ – 1480psi – Flanged – 3 phase – 8″ Meter – Skid Mounted

- Separator – 48″ x 12′ – 1480psi – 3 phase – 8″ Meter – Skid Mounted

- Separator – 36″ x 10′ – 2000psi – 3 phase – 6″ Meter – Skid Mounted

TEST SEPARATORS -SKID MOUNTED TWO STAGE

- Separator – Dual Stage – 30″ x 8′ 1440psi – 30″ x 8′ 250psi – Skid Mounted

- LP Separators and Scrubbers

- Super Separator – 90″ x 10′ – 75psi – 90bbl – 2 Phase – Skid Mounted

- Super Separator – 90″ x 10′ – 200psi – 90bbl – 2 Phase – Skid Mounted

- Super Separator – 90″ x 10′ – 200psi – 90bbl – 3 Phase -Skid Mounted

- Flare Scrubber – 4″ – 40 MMCF – Skid Mounted

- Flare Scrubber – 4″ – 60 MMCF – Skid Mounted

- HP Scrubber – 42″ x 12′ – 1440psi – 2 Phase – Trailer Mounted

- Surge Tank – 72″ x 20′ – 285psi – Vertical – 100 bbl – Skid Mounted

- Metering Skid – 2″ & 3″ – Skid Mounted

Flare Stacks

FLARING EQUIPMENT

- Flare Stack – 5″ x 60′ – Vertical – Skid Mounted

- Flare Stack – Dual 4″ x 60′ – Vertical – Skid Mounted

- Flare Stack – 4″ x 50′ – Vertical – Trailer Mounted

- Flare Stack – 6″ x 60′ – Vertical – Smokeless – Hydraulic Lifted – Trailer Mounted

- Flare Stack – 8″ x 60′ – Vertical – Hydraulic Lifted – Trailer Mounted

- Flare Stack – Stubby – 4″ x 25′

- Propane Tank – DOT – 288gal – Skid Mounted

- Propane Tank – DOT – 499gal – Skid Mounted

- Propane Rack – DOT – Four 25gal bottle – Skid Mounted

- Propane Blanketing System for Storage Tanks

- Flare Stack Igniter System – Electric

- Flare Scrubber – 4″ – 40 MMCF – Skid Mounted

- Flare Scrubber – 4″ – 60 MMCF – Skid Mounted

- HP Scrubber – 42″ x 12′ – 1440psi – 2 Phase – Trailer Mounted

- Surge Tank – 72″ x 20′ – 285psi – Vertical – 100 bbl – Skid Mounted

OFFSHORE EQUIPMENT

- Flare Boom – 45′

- Flare Boom – 55′

- Flare Boom – 60′

- Flare Boom – 80′

- Flare Boom – 90′

- Flare Boom – 90′ – Deepwater Dynamic Load

Early Production Facilities

Full production set ups available based upon specific requests.

Piping/Iron and Valves

PIPING AND FLOW – LINE FITTINGS

- Pipe – 10,000psi – 2″ 1502 – H2S – Integral -100′ w/Ten (10) 90’s

- Pipe – 15,000psi – 2″ 1502 – STD – Integral – 100′ w/Ten (10) 90’s

- Pipe – 15,000psi – 2″ 1502 – STD – NPST – 100′ w/Ten (10) 90’s

- Pipe – 2,000psi – 3″ 602 – STD – NPST – 100′ w/Ten (10) 90’s

- Pipe – 5,000psi – 3″ 602 – STD – NPST – 100′ w/Ten (10) 90’s

- Pipe – 10,000psi – 3″ 1502 – H2S – Integral – 100′ w/Ten (10) 90’s

- Pipe – 15,000psi – 3″ 1502 – STD – Integral – 100′ w/Ten (10) 90’s

- Pipe – 15,000psi – 3″ 1502 – STD – NPST – 100′ w/Ten (10) 90’s

- Pipe – 1,400psi – 4″ 206 – STD 100′ w/Ten (10) 90’s

- Pipe – 2,000psi – 4″ 206 – STD 100′ w/Ten (10) 90’s

- Pipe – 2,000psi – 4″ 206 – Certified 100′ w/ Ten (10) 90’s

- Pipe – 15,000psi – 2″ 2202 – H2S – Integral – 100′ w/Ten (10) 90’s

- Pipe – 1,480psi – 4″ ANSI 600RF – Flanged – 100′ w/Ten (10) 90’s

- Pipe – 1,480psi – 8″ ANSI 600RF – Flanged – 100′ w/Ten (10) 90’s

- Elbow – 10,000psi – 2″ 1502 – H2S – Integral – 90 Deg

- Elbow – 15,000psi – 2″ 1502 – STD – Integral – 90 Deg

- Elbow – 15,000psi – 2″ 1502 – STD – NPST – 90 Deg

- Elbow – 15,000psi – 2″ 2202 – H2S – Integral – 90 Deg

- Elbow – 2,000psi – 3″ 602 – 90 Deg

- Elbow – 5,000psi – 3″ 602 – 90 Deg

- Elbow – 10,000psi – 3″ 1502 – H2S – Integral – 90 Deg

- Elbow – 15,000psi – 3″ 1502 – STD – Integral – 90 Deg

- Elbow – 15,000psi – 3″ 1502 – STD – NPST – 90 Deg

- Elbow – 1,400psi – 4″ 206 – 90 Deg

- Elbow – 2,000psi – 4″ 206 – 90 Deg

- Elbow – 2,000psi – 4″ 206 Certified- 90 Deg

- Elbow – 600RF – 4″ Flanged – 90 Deg

- Elbow – 600RF – 8″ Flanged – 90 Deg

- Tee – 2,000psi – 2″ 206

- Tee – 10,000psi – 2″ 1502 H2S – Integral

- Tee – 15,000psi – 2″ 1502 – STD – Integral

- Tee – 15,000psi – 2″ 2202 – H2S – Integral

- Tee – 2,000psi – 3″ 602

- Tee – 5,000psi – 3″ 602

- Tee – 10,000psi – 3″ 1502 – H2S – Integral

- Tee – 15,000psi – 3″ 1502 – STD – Integral

- Tee – 1,400psi – 4″ 206

- Tee – 2,000psi – 4″ 206

- Crossover – 5,000psi – 2″

- Crossover – 10,000psi – 2″

- Crossover – 15,000psi – 2″

- Crossover – 2,000psi – 3″

- Crossover – 5,000psi – 3″

- Crossover – 10,000psi – 3″

- Crossover – 15,000psi – 3″

- Crossover – 1,400psi – 4″

- Crossover – 2,000psi – 4″

- Crossover – 10,000psi – 4″

Heaters and Filters

INDIRECT-FIRED HEATERS

- Line Heater – 2″ – 10,000psi – 750M BTU/hr – Trailer Mounted

- Line Heater – 2″ – 10,000psi – 1MM BTU/hr – Skid Mounted

- Line Heater – 2″ – 15,000psi – 1.5MM BTU/hr – Skid Mounted

- Line Heater – 3″ – 5,000psi – 1.5MM BTU/hr – Skid Mounted

- Line Heater – 3″ – 10,000psi – 2MM BTU/hr – Skid Mounted

MISCELLANEOUS EQUIPMENT FOR HEATERS

- Heater Bypass Manifold – 2″ – 10,000psi – Single Valve

- Heater Bypass Manifold – 3″ – 10,000psi – Single Valve

- Heater Bypass Manifold – 2″ – 15,000psi – Single Valve

SKID MOUNTED STEAM HEAT PACKAGES

- Steam Exchanger – 4″ – 10,000psi – 7MM BTU/hr – Skid Mounted

FILTER & SCRUBBER

- Scrubber 1330PSI Vert. Skid Mounted 60IX18FX10F

- Filter Housing 1,480PSI Horz. Skid Mounted -7CART 24IX8F

Pig Traps

TRAPS, Etc.

- 12″ ANSI 600# Launcher/Receiver

- 10″ ANSI 600# Launcher/Receiver

- 8″ ANSI 600# Launcher/Receiver

- 16″ ANSI 150# Launcher/Receiver

- Transmitter

- Geophones

- Dead Weight Tester

- Dew Point Tester

- Pressure/Temperature Recorder

- 48′ Float Trailer (Gooseneck)

- Chemical Injection Triplex Pump

- Hydrotest Pump (2 x 2) Two Stage

- Pneumatic Impact Wrench with Sockets

Project Management

Stric-Lan project managers can handle a wide variety of projects and specific jobs that you may not have the personnel or specific expertise to handle. Stric-Lan project managers can handle many types of projects including, but not limited to:

- Production Oversight

- Facility Management

- Early Production Facilities

- Well Test and Flowback Site Management

- Pipeline Project Oversight

- Pipeline Pigging, Testing & Cleaning Oversight

- Various other specific projects

Production Watch/ Well Tending

Stric-Lan personnel has extensive experience with production equipment and managing sites. This includes everything from water and oil hauling to running customers equipment.

Pipeline Projects & OQ work

Stric-Lan has experienced pipeline personnel with OQ training who can manage and oversee a wide variety of projects including midstream, facilities, plants and others. We’ve worked in every state including Hawaii and Alaska, and we’re ready to assist with any sized project so that your personnel can take care of their most critical tasks.

Offshore or Land

Stric-Lan has numerous personnel who can manage and handle project offshore or on land. We have all of the training for both offshore and land, and we’re always adapting and upgrading our training to handle increased requirements for any client’s needs.

Facility Oversight

Stric-Lan’s project managers can oversee production locations, processing facilities, pipeline locations, portions of plants and other facilities as needed. Highly experienced personnel can get the job done when you’re experiencing excessive demand on personnel and equipment. This includes early production facilities with Stric-Lan equipment installed on a semi-permanent or longer term basis.